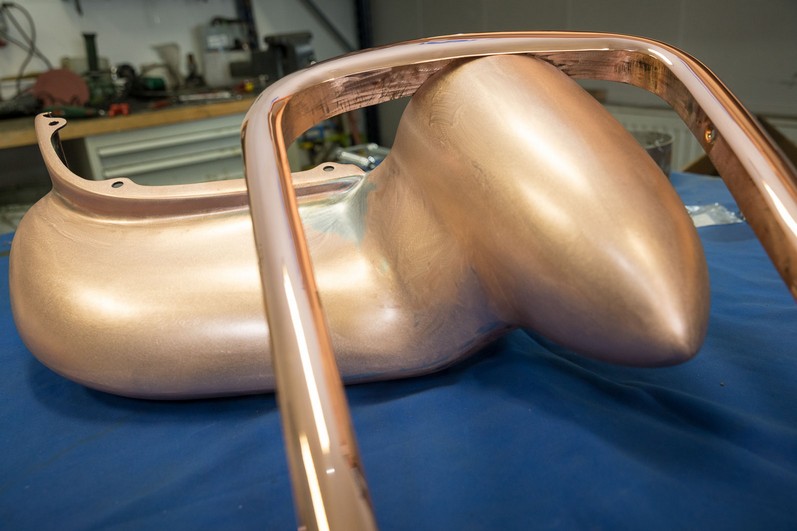

The process of chrome plating

Here we prepared for you a visual description of individual steps during the renovation of chromic parts and their chromium plating. If you click on indents, you will see photos and videos. You can see videos in our video-archive as well.

Chrome plating is the way of galvanic coating of which anode is a hard lead with minimum content of antimony (6 %; chrome is in electrolyte an anion). Chromic acid with the addition of vitriol acid, hydrofluoric, silicofluoric or acetic acid is an electrolyte.

By the galvanic chromium plating a very dense and hard adhesive protective cover is originated. Chrome resists atmospheric influences, water, acids (not salt acid and warm vitriol acid), lye, ammonia, hydrosulphide, combustion gas. It is used as a protection against corrosion. Chrome does not lose its gloss as nickel or silver, because of chromium plating it is most equable decorative galvanized.

Highly shiny chrome reflects 65% of light beams.